Origin and classification of painting equipment. Since the 1960s, due to the development of light industry, automated production lines first appeared in the bicycle manufacturing industry. During this period, the main task of my countrys coating equip…

For the use of painting equipment, a lot of requirements have been relaxed now, and professional personnel are no longer required to operate it. Ordinary people can also get the equipment and start using it. At the same time as this universality has b…

This article mainly introduces the maintenance of automatic coating equipment. If you are interested in it, you can take a look.Wipe the surface of the coating equipment clean to protect the surface paint of the equipment. The air inlet filter, filter…

There are many types of spraying machines. Among them, the position of automatic spraying machines is particularly important. Next, lets talk about the …

Test fixtures have been widely used before the industrial age, including mechanical fixtures, woodworking fixtures, welding fixtures, jewelry fixtures, and other …

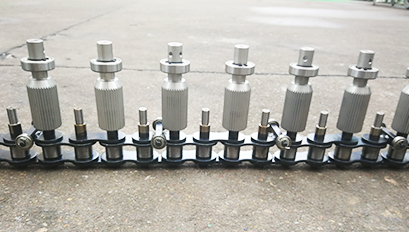

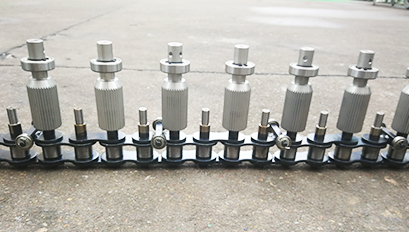

Types of chainsThere are many types of chains, which can be divided into transmission chains, conveying chains, decorative chains, cable-tightening chains and …

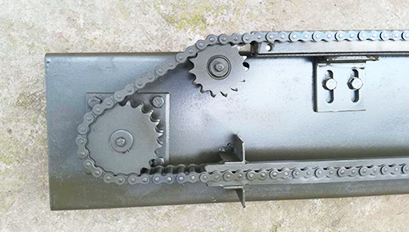

The frame is usually welded by section steel. The chain conveyor equipment uses the chain as the main working part. The chain is the main body of the load, and the chain is a flexible structure. Therefore, the chain of the load bearing part must be su…

Here is an introduction to the use and maintenance of the chain:1. Because it is impossible to understand the planning and function of the machine (especially a new operator), the chain is simple because of operating errors that cause shortcomings, an…

One: Air lines of spraying fixture: Irregular blocks appear on the coating surface, most of which are round, the color is darker than other parts, and the surface is rough.Reason: The air in the mold is not completely eliminated during forming. Sprayi…

The content of the process design mainly includes: the pretreatment method of the surface coating quality requirements of the workpiece, the spraying method, the process flow, the coating performance, the spraying environment, and the time.1. Purpose …

1. The sprocket should be installed on the shaft without skew or swing. The end faces of the two sprockets in the same transmission assembly should be in the same plane. When the center distance of the sprocket is less than 0.5 meters, the allowable d…

The quality of the design of the coating equipment process layout is crucial to the use of the coating production line. If the process layout of the coating equipment is improper, even if the individual equipment is made well, the entire coating produ…

Spraying jig operation skills1. The purpose of mastering the correct operation skills of spraying jigs is to save paint, obtain coatings that meet the quality requirements, avoid the consumption of paint quality and physical strength, and reduce the p…

Fixture is a device used to fix the processing object in the mechanical manufacturing process so that it occupies the correct position to accept construction or inspection.1. Positioning componentsIt is in contact with the positioning datum of the wor…

Yongkang Gushan Quanying Hardware Factory was established in 1999. Zhejiang Yongkang Gushan Quanying Hardware Factory specializes in the production and processing of various transmission accessories such as: spraying jigs, mesh belts, string rods, rol…

Solution treatment is to heat the casting to the highest possible temperature, close to the melting point of the eutectic. The higher the temperature, the faster the dissolution of strengthening elements and the better the strengthening effect. Genera…

In the past, the production and processing of die-casting molds mainly relied on fitters, or the extensive workshop-style production management model centered on fitters, but now it is gradually being replaced by an intensive modern production managem…

(1) Personnel entering and exiting the clean room of spraying jigs should observe: spraying jigs1. Management of entering the clean room of spraying jigs 1.1 Before entering the paint shop, any personnel should change shoes and clean clothes in the lo…

Because of the high hardness of the surface of the gear after heat treatment, the traditional hot post-processing process is to process the hole after clamping the pitch circle of the workpiece with a hole-grinding fixture. The advantage of this proce…

In the technical field of spraying jigs, it specifically refers to an automatic spraying jig for laminating two-layer substrates. It is achieved by the following technical solution: the automatic spraying jig includes a first substrate unwinding devic…